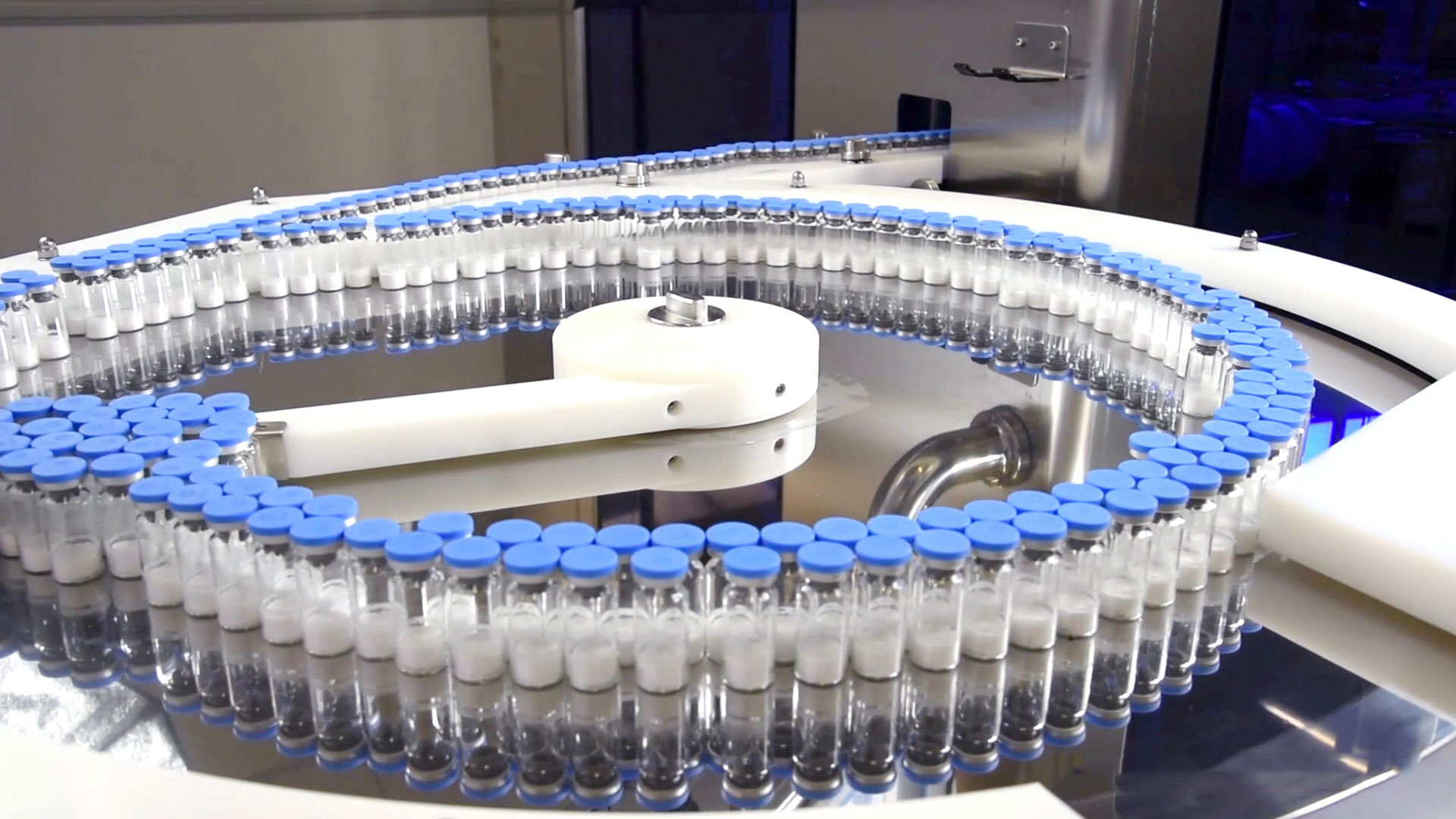

The LYO-CHECK is an automatic industrial machine designed for the visual inspection of lyophilized pharmaceutical preparation for

injectable use (parenteralia).

The LYO-CHECK machine exploits two technologies for a full inspection of the lyo products: visual inspection for foreign matters on the product, cosmetic and functional defects on the primary container; moreover the machine can be equipped with Head Space Gas Analysis for cointainer closure integrity.

The machine belongs to a range of equipment goes up to whose capacity up to 600 containers/minute.

Reject verification system based on “fail-safe” principle ensures that containers recognized as defective will not reach the exit channel of good products.

The machine can be run by a single operator through the built-in touch-screen display, where all the controls and configuration functions are available on a FDA 21CFR11 compliant Graphic User Interface.

BENEFITS

AND ADVANTAGES