DISRUPTIVE TECHNOLOGY

PATENTED SOLUTIONS

WIDER INSPECTION SPACE

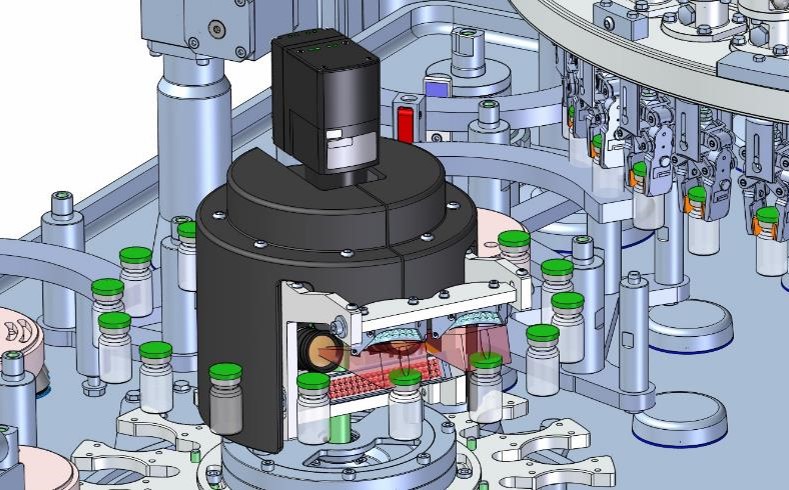

Exclusive main inspection carousel design features a combination of grippers and column-free configuration

The machine main inspection carousel has a patented design without central column and without conventional spindles to hold the products, allowing:

1) The cameras to be placed at a bigger distance from the object, thus obtaining the perfect focus

without need for re-adjustment

2) The lighting source to be placed on different sides around the product to be inspected

as per conventional configuration

3) Cameras to be angled (rather than pointing straight at the product)

PERFECT LYO CAKE INSPECTION

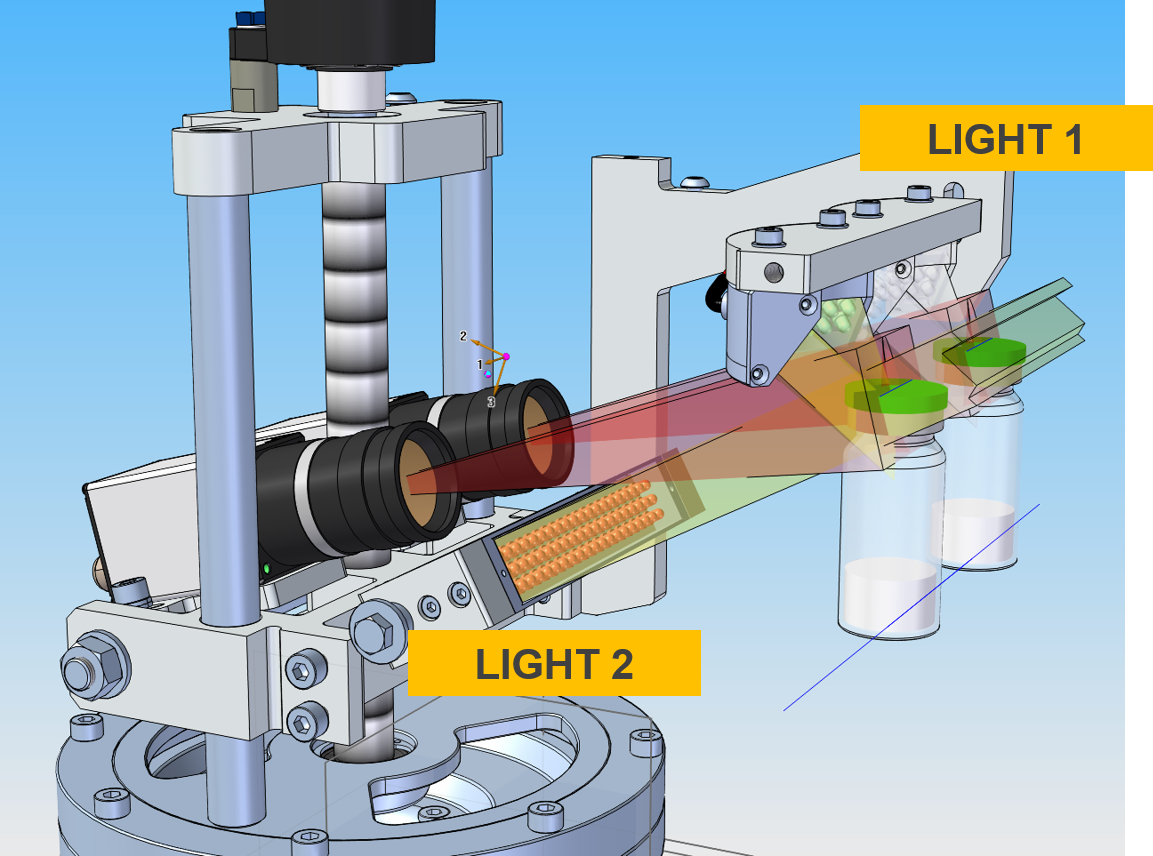

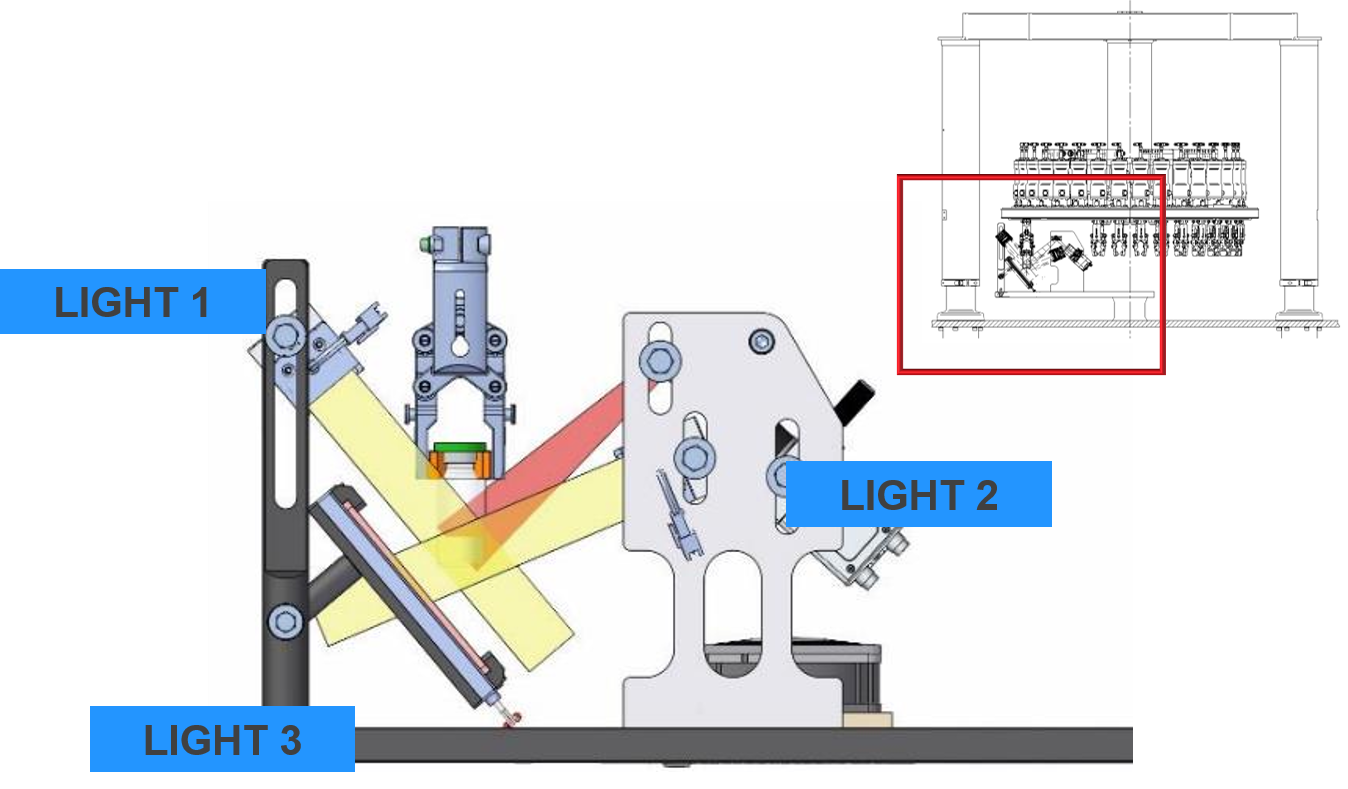

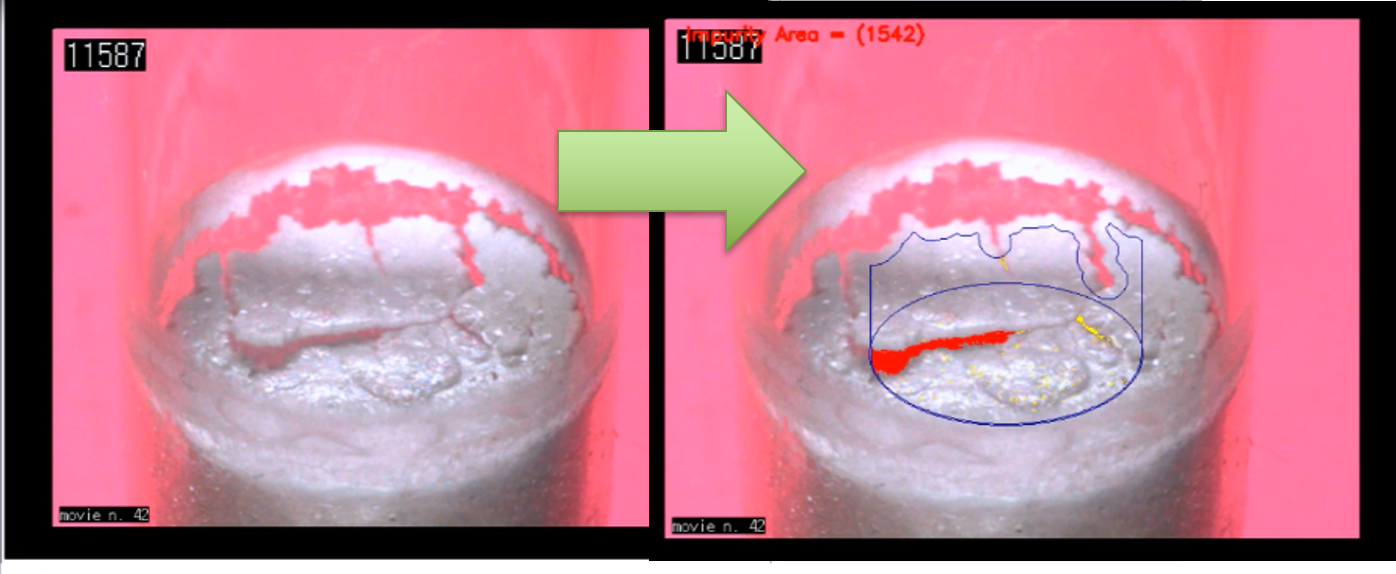

Proprietary optical architecture features three different lighting sources

A patent has been filed for a specific optical layout that targets the upper portion of the lyo cake. This is formed by three different lighting sources, with a specific angle of incidence towards the product, and with a specific intensity (lux).

The result is a much higher quality of the images that are acquired, which eliminates almost all shadowy effects that are present on the morphology of the lyo cake for foreign matters thus minimizing false rejects. In this way the «moon-like» surface of the lyo cake can be properly inspected.

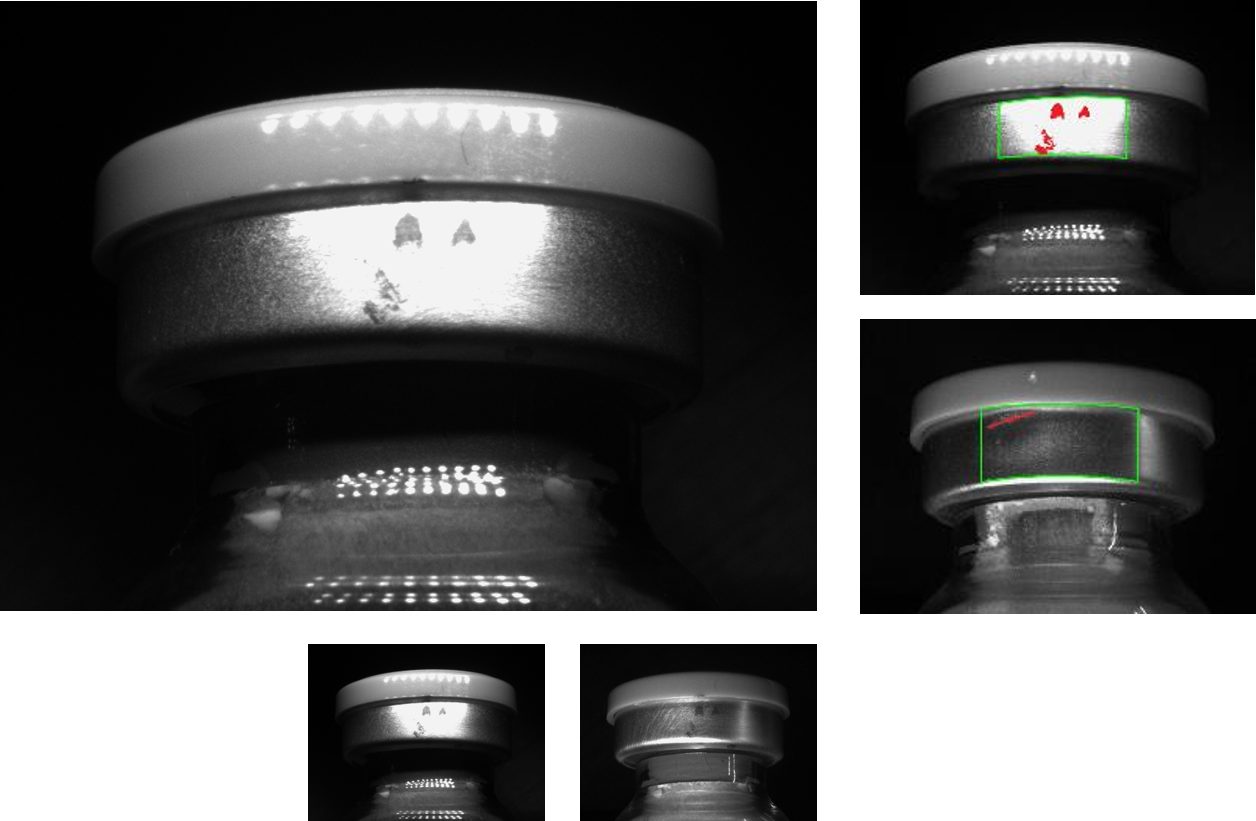

HIGH PRECISION CRIMP INSPECTION

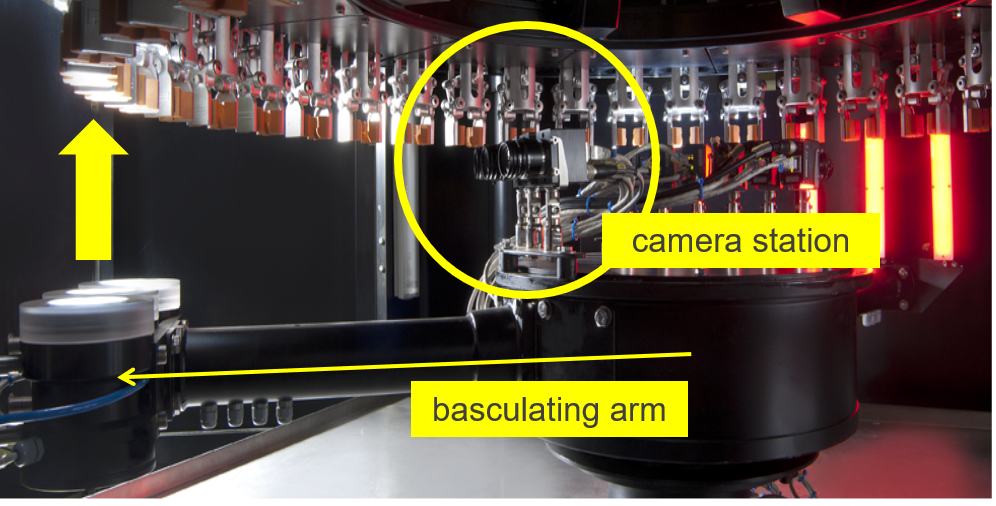

Dynamic seal inspection for the quality of the crimped aluminum seal of the vial using second carousel

A patent has been filed for a specific design of a new type of inspection station dedicated to crimping and neck inspection. The station is based on a dynamic inspection which exploits an external turret (or second carousel) composed of a series of cameras and at least two types of lighting sources: from the top and from the bottom. Each light type has therefore a different angle of incidence versus the zone to be inspected and allows for the creation of a different environment, helping to maximize the defect visibility. The container is put in rotation 360° and the cameras - installed onto a tilting arm - follow the product along the path.

The inspection machine design WITHOUT the central column has three immediate benefits

In the machine used for the test, the design of the central carousel without inner column is paired with other two innovative functional solution:

LIGHTS:

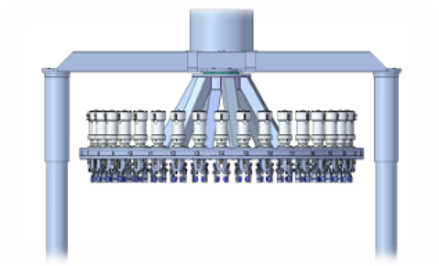

SECOND CAROUSEL

A patent has been filed for a specific design of a new type of inspection station dedicated to crimping and neck inspection.

The station is based on a dynamic inspection which exploits a second carousel composed of a series of cameras and at least two type of lighting sources: from the top and from the bottom. Each light types has therefore a different angle of incidence versus the zone to be inspected and allows for the creating of a different environment helping to maximize the defect visibility.

The container is put in rotation 360° and the cameras – installed onto a basculating arm – follow the product along the path