Antares Vision has been awarded an important grant from the European Commission, within the EU Horizon 2020’s SME instrument framework, to develop a new technology for the inspection of lyophilized pharma products for injection : the LYO-CHECK machine project.

The result of this research is going to represent a disruptive innovation in the field of inspection for the whole pharma industry.

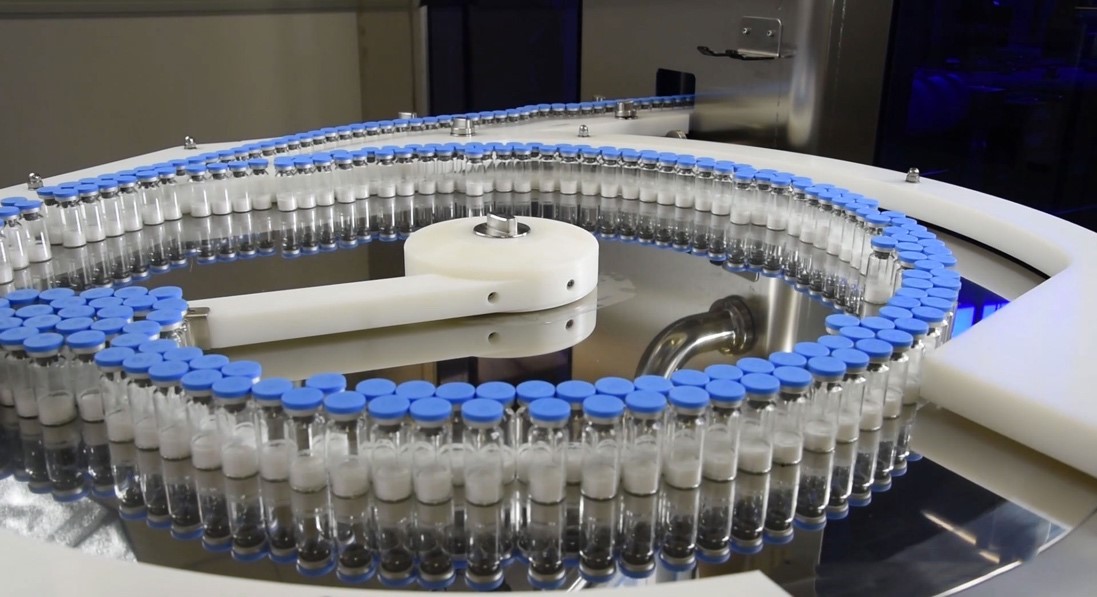

Pharmaceutical products intended for injection are becoming more and more commonly found in lyophilized form and this trend appears to grow steadily, especially for anti-infectives, biotechnology derived products, and in-vitro diagnostics, because the lyophilization process allows to treat, without damaging, ingredients that are unstable, heat-sensitive, or simply not miscible in water. Moreover, the lyophilized products have two main advantages: they are long-term storable - more than two years - and easy to stock, even at room temperature; they have a rapid reconstitution in contact with the appropriate solvent, preserving the original product features.

The worldwide pharmaceutical market is generally driven by the necessity of a constant increase in product quality in order to ensure patient safety and product compliance, as well as an increase in production output, in order to reduce the overall costs of the pharmaceutical products making them available to a wider spectrum of users.

Since the lyophilized form is set to become the most widely used in the production of high added-value preparations for injection, the increase in product quality and production output is a current top priority, that can be achieved only by the combination of different factors and improvement strategies, which are being taken into account in the development of the LYO-CHECK machine.

The quality-control inspection of products in lyophilized form poses anyway peculiar challenges, thus creating the need for an innovative dedicated system which is totally different from the ones so far commonly applied to inspect parenteral products in liquid form..

The LYO-CHECK project is split in two phases whose result will be the development of a fully automatic industrial machine for 100% inspection of freeze-dried parenteralia based on

1. an innovative vision architecture (dedicated software and dedicated optical layout), for which Antares is submitting several patent applications

2. combined with an ancillary technology (HSGA - Head Space Gas Analysis) for testing the sterility and the integrity of the product via container closure inspection.

The new automatic inspection process performed with the LYO-CHECK machine will impact the lyophilized products sector in terms of a higher quality of product due to lower inspection errors (higher accuracy and therefore less false rejects), lowering the overall process cost compered to manual inspection.

****

Horizon 2020 is the biggest EU Research and Innovation programme ever, with nearly 80 billion euros of funding available over 7 years (2014 to 2020) and is highly selective: of more than 20,000 applications in the first 2 years, less that 6% of the projects have been approved for funding.

In the words of Adriano Fusco, Strategy and Development Director: “Antares Vision is widely recognized as the world leader in serialization technology for the pharma industry, but this grant acknowledges we are also very active in our other key business areas. The company research and development team features some of the world’s best specialists in visual inspection, and this is only the first result of many more to come from our research centre”.

“The Inspection machines division has obtained extraordinary results in the last three years, launching several systems that represent a real breakthrough in the market” confirms Davide Sacchetti, Business Development Manager for Inspection Machines. “For example, several major multinational companies manufacturing large volume parenteral products have already chosen Antares Vision’s solutions for combined vision inspection and leak detection, thanks to high-performance vision and software architecture allowing to inspect through matt plastic, typical of the blow-fill-seal process, since no competitors could offer a reliable and consistent solution”.

“This latest achievement recognizes the outstanding work conducted by the research team, which always takes into account the three pivots of all Antares’ inspection machines technology: perfect mechanical handling; dedicated optical layout which is product-related; advanced algorithms for consistent software judgment. The same principles and criteria will be adopted while designing the upgraded version of the LYO-CHECK inspection machine”.

During the LYO-CHECK project, the new pilot and industrial machines will be employed for demonstrations in operational environment, with trials on potential customer’s products.

###

About Antares Vision

Antares Vision transforms knowledge and technology into solutions and best practices for the pharmaceutical industry and therefore, ultimately, for patients and for all of us.

Recognized as the world’s leading provider of serialization-based track and trace solutions for the pharmaceutical industry, by the end of 2016 Antares Vision had installed solutions on over 1000 production lines in 170 plants around the world. More than five billion stock keeping units (SKUs) have been serialized, aggregated, shipped, and notified utilizing Antares Vision solutions.

Comprising both hardware and software, Antares Vision’s solutions stem from strong relationships with best-in-class technology vendors, including enterprise application suppliers, packaging OEMs, manufacturers of cameras, printers and labelers, software and communication providers.

Antares Vision Corporate headquarters is in Travagliato, Brescia, Italy.

For more information, visit www.antaresvision.com.